Building a house from environmentally friendly materials

Today, skyscrapers can be built of wood, a straw bale house can be ordered from a factory and an earth building can be ‘printed’ with a large 3D-printer. All this allows natural materials to be used faster and more conveniently in the building and finishing of ever larger and increasingly diverse buildings.

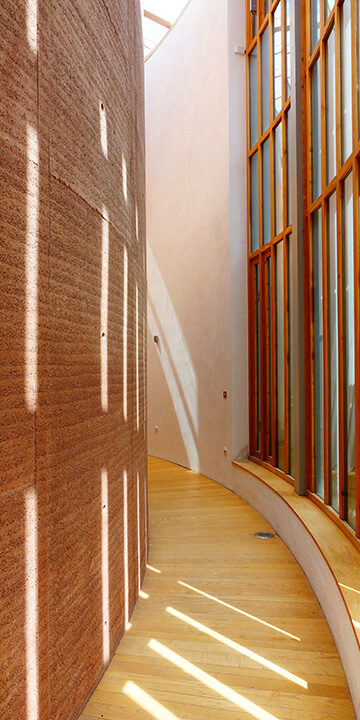

Material: rammed earth / Building: The WISE building, Center for Alternative Technology / Architect: Pat Borer & David Lea Architects / Location: Machynlleth, Wales / Photo: © Alice Reed

Private person

Architect

Developer

Builder

Modern building

The key words of a modern building are energy efficiency, environmental friendliness, and sustainability. We spend 85–90% of our lives indoors, therefore it is crucial to pay attention to the materials – building materials, finishing materials, furniture, textiles – that we surround ourselves with.

In recent decades, the energy efficiency of buildings has received increasing attention; we would take a big step towards climate neutrality if the best standards were actually widely applied. The passive house standard (optional) and the requirements for a nearly zero-energy building have been introduced, building codes have become more stringent, but unfortunately, none of the above set requirements for the life cycle of the materials used, offering a half-way solution.

Energy efficiency and environmentally friendly materials need to go hand in hand. Hopefully, laws and standards will reach this point; in the meantime, it is the joint responsibility of all of us, the customers, designers, and builders, to keep in mind the following when selecting the materials:

- as little energy as possible should be spent on the production and transport of the materials (primary energy content);

- as little energy as possible should be spent on the maintenance, use, renewal, or replacement of the materials (operational energy content);

- during the installation and use cycle of the materials, no compounds harmful to the environment or the indoor climate of the buildings should be released;

- the materials need to be reusable or their disposal should not harm the environment.

We spend 85–90% of our lives indoors, therefore it is crucial to pay attention to the materials that we surround ourselves with. Natural materials can be used to create very modern finishes, and these can also be used on all the more common base surfaces.

Modern straw bale houses

Modern professional straw building is rapidly moving towards the production of prefabricated panels. This will help speed up building work on the construction site and the building will also become weatherproof more quickly.

The construction of apartment buildings, schools, and other public buildings from straw panels has already become very popular in Western European countries. Currently, the world’s tallest straw-insulated building is a 7-story passive house in France, but a 12-story building will be built in Sweden in 2024.

Interior finishing with clay and lime plaster

Clay and lime plasters support a healthy indoor climate and are an integral part of a modern building. A wide range of materials and installation and decorative techniques offers the opportunity to achieve unique results.

In addition to good properties and visual aesthetics, the ecological footprint of the production and transport of world-class natural finishing materials produced in Estonia is tens of times smaller than that of common materials.

Modern rammed earth

Rammed earth technique allows to build beautiful, durable, ecological, and sustainable solutions in modern building, both indoors and outdoors – mainly the walls, but also the floors, furniture, and design elements.

Similar to the trend in other building materials, more innovative companies have started to produce rammed earth panels under factory conditions. There are also more and more examples of modern use of rammed earth in the production of stationary furniture and design elements.

Tadelakt

Tadelakt is still a hugely growing trend and an ideal natural alternative instead of using for example, ceramic tiles in damp rooms to create jointless silky surfaces that can also be curved, if need be.

Tadelakt can also be used as a finishing material in other rooms as well for covering ovens, and as a design and interior design element and is a perfect material for those who prefer a personalised and unique surface finish.

Contact

Eestimaaehitus MTÜ

E-mail: tere@eme.ee

Phone: +372 56 226 066